The first documentary reference to the mill (»Steinbruckmühle«) dates back to 1031.

Alongside the main business as a grain mill, the operation of a sawmill is started in 1890, and is continuously expanded over the following decades.

In 1991, the 5th generation, in the person of Franz Wagner, takes over the business. International business connections are made and extended.

We are PEFC certified and only process wood from guaranteed sustainable forestry management systems!

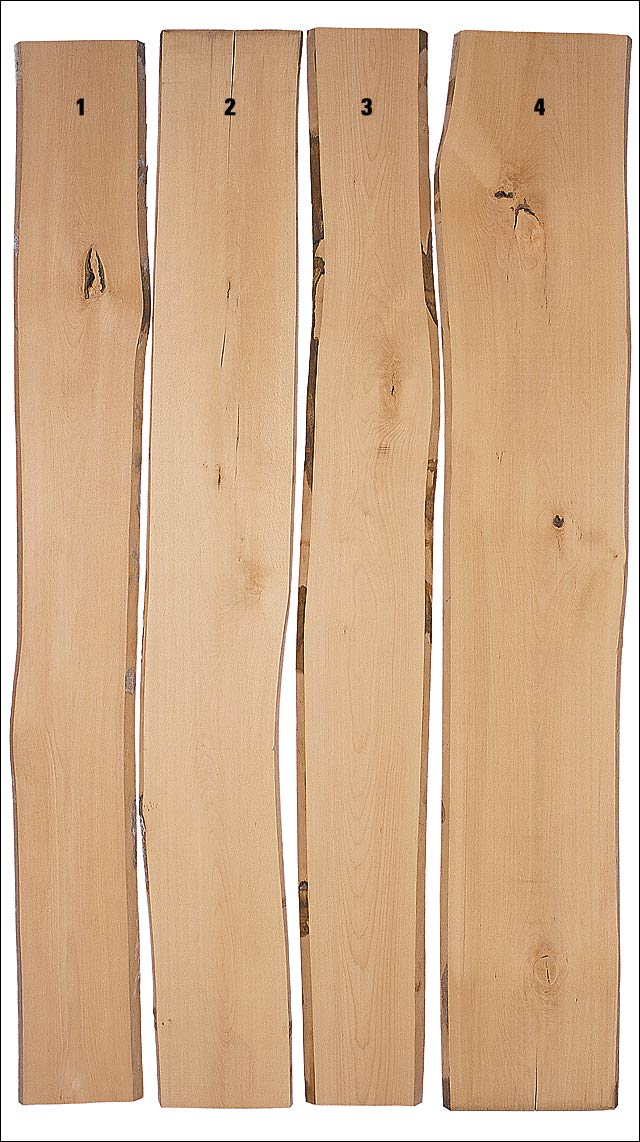

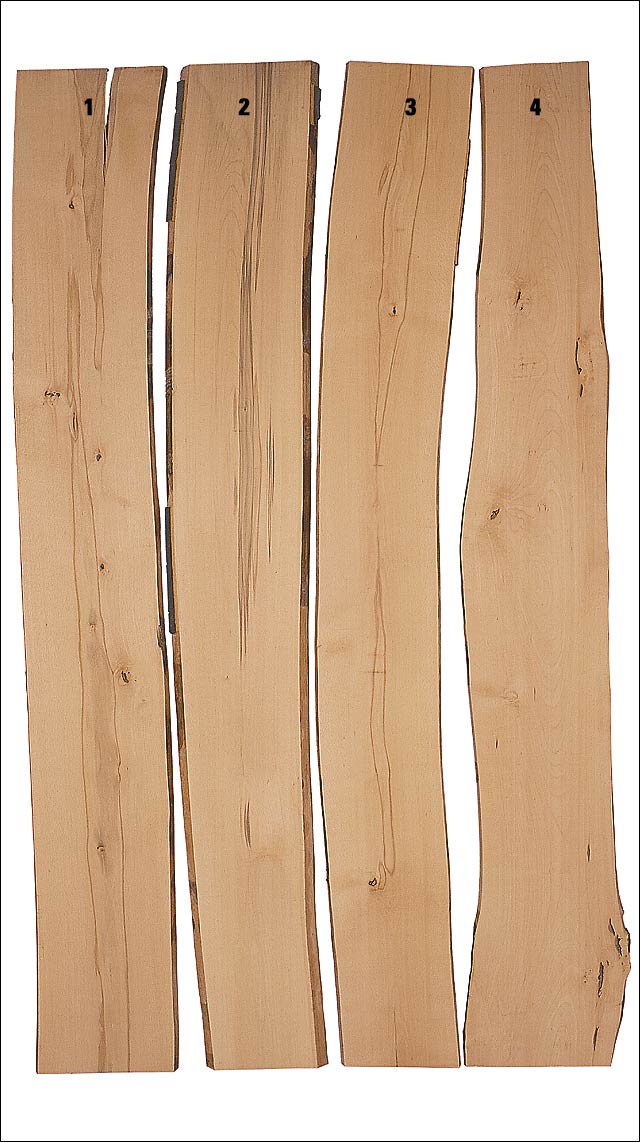

The round timber is cut only on ribbon saws, to ensure the highest quality and fullest use of the wood in the sawn timber production.

The wood comes directly from the saw into the right chambers for further processing. In order to be able to meet our customers' expectations of high quality, it is necessary for our steam and drying chambers to have an adequate capacity.

For the drying i.e. after the steaming process, the boards or poles are stacked on sunk laths.

Finished packages, measured and stacked by hand, are stored in air-conditioned halls. A constant level of 8–12% humidity can thus be guaranteed for chamber-dried wood.

One important area of our production covers the further processing of sawn timber into elements for the construction of instruments, furniture and parquet floors.

Our product range:

Beech, Oak, Ash, Maple, Pear, Acacia, Cherry, Plum, Norway Maple, Walnut, Elm, Lime, Hornbeam, Alder, Birch, Apple...

Managing Director

Office

Production Manager

Office

Steinbruckmühle 1 · 3314 Strengberg · Austria

Tel. +43 (0)7432/2288

Fax +43 (0)7432/2288-2

office@wagner-hardwoods.com

UID-Nr. ATU63370079

FIBUNr. 292443p

All Rights Reserved | Copyright 2016 © The Bizium template by pFind's Goodies